Autonomy in Farming: What Manufacturers and Tech Companies Are Working On

Companies are rolling out autonomous capabilities today with the goal of eventual full autonomy in the future.

Matthew J. Grassi • October 17, 2024 07:19 AM

Smart Farming Autonomy in Ag

A bold, new era marked by mass adoption of autonomous machines is nearing realization. Farmers are more interested than ever in the shift to full automation.

Ohio State University professor John Fulton points to the current farm economy as one catalyst driving interest. He believes challenges in recruiting skilled labor and an increasing comfort with technology will continue to advance buy-in from growers.

“You’re going to see more of it being embedded into machines, and we’re right on the cusp of seeing more autonomy adopted by farmers,” Fulton says.

Let’s dive in and explore what some companies developing autonomous solutions have been working on.

Retrofitting Robotics

Sabanto is developing retrofit kits to convert existing tractors into autonomous machines. The approach is grounded in founder and CEO Craig Rupp’s belief the next generation of highly capable, high horsepower tractors – what he deems the “Swiss Army Knives” of farming – are already in farmers’ machine sheds.

Rupp says rather than buying a new tractor with the latest autonomy features, farmers should first explore upgrading their current machines. Installation of Sabanto’s retrofit autonomous tractor kit is available today on John Deere’s 5E and 6E Series, as well as Kubota and Fendt models.

Sabanto is focusing on integrating farmer feedback into its autonomous tractor kits.

One potential low-hanging fruit is autonomous field-to-field traversal. This would shuttle the tractors autonomously between fields connected by a private drive, and someday do the same on public roads. Autonomous machines today are trailered from field to field.

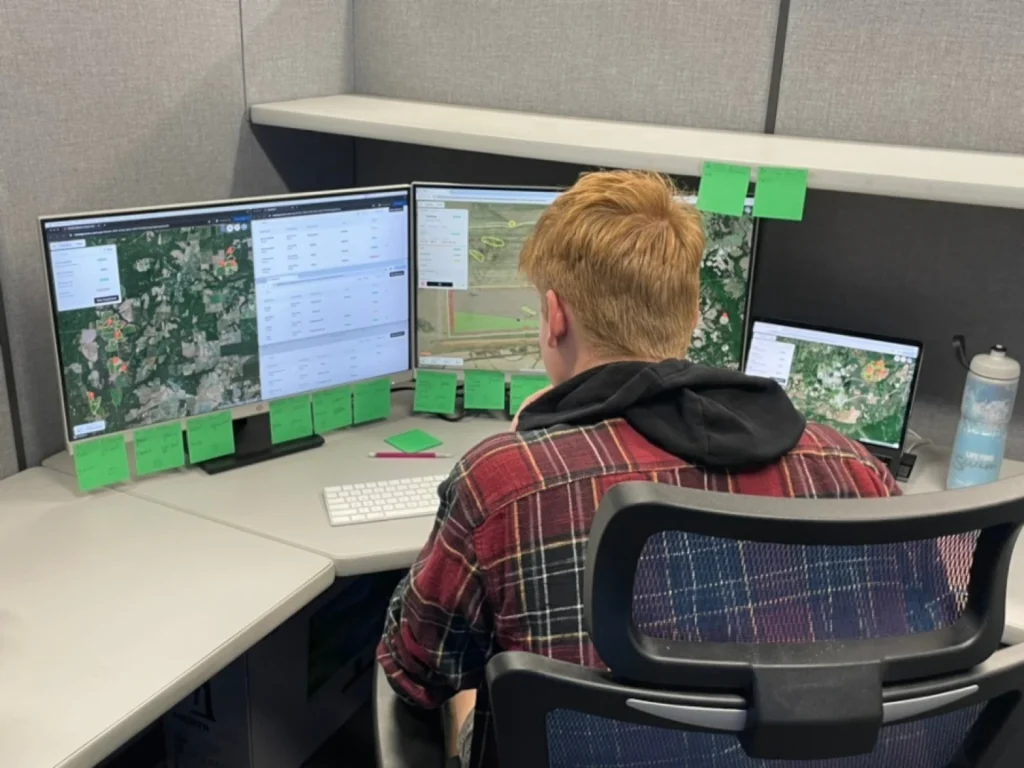

Sabanto is also forming a team of virtual field operators, made up of young people with experience in farming simulators, Rupp says. These operators will remotely oversee and control Sabanto machines across the country. After a farmer trailers a tractor to a field and unloads it, the virtual operators will manage tasks and oversee in-field operations in real time.

Rupp says Sabanto engineers are also improving in-field path planning and extending active hours with the goal of running robotic tractors around the clock.

From his viewpoint, the former electrical engineer turned ag entrepreneur is convinced autonomous farming will happen at a large-scale.

“We’ve gone beyond the when and if, and we’re at the stage where it comes down to how it is going to be done,” Rupp says.

2030 or Bust?

John Deere’s transition from equipment manufacturer to data and ag tech innovator plows ahead at full steam. The manufacturers’ model year 2025 class of machines showcased more factory-installed autonomy features than any previous class in its long history.

John Deere’s runway to bringing its machines to life without an operator at the helm is short: The company is in a race against the calendar, having pledged to delivering a fully autonomous fleet of machines in corn and soybeans by 2030.

The next opportunity to learn what John Deere is planning for its row-crop technology stack looks to be the Consumer Electronics Show (CES) in Las Vegas, Nevada, in January 2025. Last year, the company showcased its 8R autonomous tractor and Furrow Vision seed furrow sensing technology.

Specialty Crop Starting Line

CNH-owned New Holland recently announced a tie up with ag robotics startup Bluewhite. The partnership will enable collaboration on distribution, manufacturing and integration of Bluewhite’s autonomous technology with New Holland tractors in North America.

According to Paul Welbig, director of precision technology, New Holland, the Bluewhite kits consist of many common components, such as front-facing LiDAR and various arrays of connected sensors around the tractor. Cursory mechanical drive components, as well as software to link everything up and make it all “talk”, or work in concert, are also included.

New Holland has also started building out its autonomy portfolio in row crops, starting with its driverless grain cart technology, Raven Cart Automation, that links up a grain cart (pulled by a tractor) and combine autonomously, removing the need for an additional driver during harvest.

https://assets.farmjournal.com/dims4/default/bed437b/2147483647/strip/true/crop/1200×857+0+0/resize/1440×1028!/format/webp/quality/90/?url=https%3A%2F%2Fk1-prod-farm-journal.s3.us-east-2.amazonaws.com%2Fbrightspot%2F5f%2F4b%2F7e952e9743b88c0f0a4c15d71981%2Fnew-holland-bluewhite-cherry-field.jpg“The practicality and return on investment [for that system] come in when you run more than one machine with only one operator,” Welbig explains. “That’s really how you start to see value; we can support multiple combine and tractor combinations – up to six machines total – today.”

Welbig and the New Holland executive team see autonomy as a five-step journey. The first step is auto guidance and GPS, and step two is ensuring all machines are connected and exchanging data. The highest level of autonomy, step five, represents a complete removal of both the driver and the farmer from the field altogether. At that level the farmer sits in a central location, managing and tasking multiple machines from a computer or tablet.

“Steps two, three and four in between, there’s still a lot of meat left on that bone,” Welbig admits. “As autonomous technology continues to evolve in the future, we’ll continue to evolve with it.”

Fully Cycle Autonomy

AGCO’s newest joint tech venture, PTx Trimble, is now solidly off the ground, and the company is advancing its autonomous grain cart tech heading into 2025.

The group’s vision of bringing autonomy to the full ag production cycle is also coming to life, although like its competitors, it’s going to take time for the full vision to come to fruition.

PTx Trimble’s automated grain cart system, OutRun.ag, will be available for purchase in 2025. For year one, single cart configuration is unlocked. The next evolution is enabling swarming of two autonomous grain carts around the same combine.

PTx Trimble also has an autonomous tillage system currently in development. The company figures many farmers will happily give up running a tillage tool across the field to a robot.

A clear differentiation point is PTx Trimble’s use of cellular connectivity and edge computing over low orbit satellite connectivity. This allows for operation in remote areas with sub-par connectivity.

RELATED: Planting A Flag: AGCO All-In On Mixed-Fleet Aftermarket Ag Tech

One limiting factor to adoption is farmer sentiment toward field work, and the types of tasks they’ll agree to give up to a machine. Ultimately, it will be up to the technology to fully prove its worth.

“As you automate you have the option of pulling the operator out [of the cab],” says Eric Hansotia, AGCO CEO. “But where is the farmer going to feel comfortable giving up that control? And can we find an autonomous solution there and build up farmer trust?”

Source: Ag Web Farm Journal | https://www.agweb.com/news/business/technology/autonomy-farming-what-manufacturers-and-tech-companies-are-working

168 Comments

На этом сайте у вас есть возможность приобрести онлайн телефонные номера разных операторов. Эти номера могут использоваться для регистрации аккаунтов в разных сервисах и приложениях.

В каталоге доступны как долговременные, так и одноразовые номера, которые можно использовать чтобы принять SMS. Это удобное решение если вам не желает использовать личный номер в интернете.

купить номер Норвегии

Процесс покупки максимально удобный: выбираете подходящий номер, оплачиваете, и он сразу будет доступен. Попробуйте услугу прямо сейчас!

На этом сайте у вас есть возможность приобрести онлайн мобильные номера разных операторов. Они могут использоваться для подтверждения аккаунтов в разных сервисах и приложениях.

В ассортименте доступны как долговременные, так и временные номера, что можно использовать чтобы принять SMS. Это удобное решение для тех, кто не хочет указывать основной номер в интернете.

купить временый номер

Процесс покупки очень удобный: выбираете необходимый номер, вносите оплату, и он сразу будет готов к использованию. Оцените сервис прямо сейчас!

Современная частная клиника предлагает современное лечение в любых возрастных категориях.

В нашем центре внимание к каждому пациенту всестороннюю диагностику.

В клинике работают высококвалифицированные специалисты, применяющие новейшие технологии.

Наши услуги включают широкий спектр медицинских процедур, среди которых медицинские услуги по восстановлению здоровья.

Забота о вашем здоровье — основная цель нашего обслуживания.

Свяжитесь с нами, и восстановите ваше здоровье с нами.

prospectuso.com

Одеяние оберегает от замерзания и палящее солнце, но и отражает индивидуальность. Некоторые выбирают наряды, чтобы выглядеть привлекательно. Некоторые считают, что, как их оценивают окружающие, поэтому стиль становится инструментом самовыражения. Помимо этого, одежда может соответствовать ситуации. К примеру, классический образ подходит для работы, а свободная одежда идеальны для повседневной жизни. Следовательно, выбор наряда имеет значение в жизни каждого.

https://artistecard.com/LePodium

На этом ресурсе вы найдете центр ментального здоровья, которая обеспечивает профессиональную помощь для людей, страдающих от стресса и других психологических расстройств. Наша индивидуальный подход для восстановления ментального здоровья. Врачи нашего центра готовы помочь вам справиться с психологические барьеры и вернуться к сбалансированной жизни. Профессионализм наших врачей подтверждена множеством положительных обратной связи. Обратитесь с нами уже сегодня, чтобы начать путь к оздоровлению.

http://jamtv.com/__media__/js/netsoltrademark.php?d=empathycenter.ru%2Fpreparations%2Fz%2Fzopiklon%2F

На этом ресурсе вы найдете центр ментального здоровья, которая предоставляет профессиональную помощь для людей, страдающих от стресса и других ментальных расстройств. Мы предлагаем индивидуальный подход для восстановления ментального здоровья. Наши специалисты готовы помочь вам преодолеть психологические барьеры и вернуться к гармонии. Профессионализм наших психологов подтверждена множеством положительных рекомендаций. Запишитесь с нами уже сегодня, чтобы начать путь к восстановлению.

http://library-pictures.com/__media__/js/netsoltrademark.php?d=empathycenter.ru%2Fpreparations%2Fl%2Flamotridzhin%2F

На данной платформе вы найдете клинику ментального здоровья, которая обеспечивает психологические услуги для людей, страдающих от тревоги и других ментальных расстройств. Наша эффективные методы для восстановления ментального здоровья. Наши специалисты готовы помочь вам решить проблемы и вернуться к психологическому благополучию. Квалификация наших психологов подтверждена множеством положительных обратной связи. Свяжитесь с нами уже сегодня, чтобы начать путь к лучшей жизни.

http://limoforbid.com/__media__/js/netsoltrademark.php?d=empathycenter.ru%2Fpreparations%2Fv%2Fvenlafaksin%2F

The GameAthlon platform is a leading entertainment platform offering dynamic games for users of all levels.

The casino provides a huge collection of slot games, real-time games, card games, and sports betting.

Players are offered fast navigation, high-quality graphics, and easy-to-use interfaces on both computer and tablets.

http://www.gameathlon.gr

GameAthlon focuses on player safety by offering encrypted transactions and transparent outcomes.

Bonuses and special rewards are constantly improved, giving players extra incentives to win and have fun.

The helpdesk is ready 24/7, supporting with any issues quickly and professionally.

The site is the top destination for those looking for entertainment and exciting rewards in one trusted space.

Предоставляем прокат автобусов и микроавтобусов с водителем корпоративным клиентам, бизнеса любого масштаба, а также частным лицам.

https://avtoaibolit-76.ru/

Обеспечиваем максимально комфортную и абсолютно безопасную доставку пассажиров, организуя заказы на свадьбы, корпоративные встречи, познавательные туры и любые события в Челябинске и Челябинской области.

Swiss watches have long been a gold standard in horology. Meticulously designed by legendary brands, they combine heritage with modern technology.

Each detail embody superior quality, from precision-engineered calibers to luxurious finishes.

Owning a Swiss watch is more than a way to check the hour. It stands for refined taste and uncompromising quality.

No matter if you love a bold statement piece, Swiss watches provide unparalleled precision that never goes out of style.

http://saschawill.de/forum/viewtopic.php?f=13&t=136530

Swiss watches have long been a gold standard in horology. Meticulously designed by renowned watchmakers, they perfectly unite heritage with modern technology.

Every component reflect superior attention to detail, from hand-assembled movements to premium elements.

Wearing a timepiece is a true statement of status. It represents timeless elegance and exceptional durability.

Be it a minimalist aesthetic, Swiss watches offer extraordinary reliability that lasts for generations.

http://216.38.0.7/viewtopic.php?f=12&t=407696

Чем интересен BlackSprut?

Сервис BlackSprut привлекает интерес широкой аудитории. В чем его особенности?

Этот проект обеспечивает интересные опции для своих пользователей. Оформление сайта выделяется удобством, что позволяет ей быть понятной даже для новичков.

Стоит учитывать, что BlackSprut обладает уникальными характеристиками, которые отличают его на рынке.

Говоря о BlackSprut, стоит отметить, что определенная аудитория выражают неоднозначные взгляды. Некоторые выделяют его удобство, другие же рассматривают с осторожностью.

В целом, BlackSprut остается объектом интереса и вызывает заинтересованность разных пользователей.

Где найти работающий доступ на БлэкСпрут?

Хотите узнать свежее зеркало на БлэкСпрут? Это можно сделать здесь.

https://bs2best

Иногда ресурс меняет адрес, поэтому нужно знать новое ссылку.

Обновленный адрес легко найти здесь.

Посмотрите актуальную версию сайта прямо сейчас!

Мы осуществляет сопровождением приезжих в северной столице.

Предоставляем услуги в оформлении разрешений, временной регистрации, а также формальностях, касающихся работы.

Наши специалисты помогают по всем юридическим вопросам и дают советы оптимальные варианты.

Мы работаем в оформлении ВНЖ, а также по получению гражданства.

Благодаря нам, ваша адаптация пройдет легче, решить все юридические формальности и спокойно жить в Санкт-Петербурге.

Свяжитесь с нами, для консультации и помощи!

https://spb-migrant.ru/

Поклонники онлайн-казино могут легко получить доступ к зеркальное обходную ссылку онлайн-казино Champion и продолжать играть популярными автоматами.

На платформе доступны различные онлайн-игры, от ретро-автоматов до современных, и последние автоматы от мировых брендов.

Если главный ресурс временно заблокирован, зеркало казино Чемпион позволит без проблем войти и делать ставки без перебоев.

чемпион слот

Все функции остаются доступными, начиная от создания аккаунта, пополнение счета и кэш-ауты, а также бонусы.

Заходите через обновленную зеркало, и не терять доступ к казино Чемпион!

Чем интересен BlackSprut?

Платформа BlackSprut удостаивается интерес разных сообществ. Почему о нем говорят?

Данный ресурс предоставляет интересные опции для аудитории. Оформление платформы выделяется простотой, что делает его доступной даже для тех, кто впервые сталкивается с подобными сервисами.

Стоит учитывать, что этот ресурс обладает уникальными характеристиками, которые отличают его на рынке.

Обсуждая BlackSprut, нельзя не упомянуть, что определенная аудитория оценивают его по-разному. Многие выделяют его функциональность, а некоторые рассматривают более критично.

Подводя итоги, BlackSprut остается предметом обсуждений и привлекает заинтересованность разных слоев интернет-сообщества.

Ищете рабочее зеркало БлэкСпрут?

Хотите узнать актуальное ссылку на BlackSprut? Мы поможем.

bs2best актуальная ссылка

Сайт часто обновляет адреса, и лучше знать актуальный домен.

Мы мониторим за актуальными доменами чтобы предоставить новым линком.

Проверьте актуальную ссылку прямо сейчас!

This website offers plenty of video slots, suitable for all types of players.

On this site, you can explore traditional machines, feature-rich games, and huge-win machines with stunning graphics and realistic audio.

No matter if you’re into simple gameplay or prefer bonus-rich rounds, you’ll find a perfect match.

https://lorenzoorpl78999.bloginwi.com/67456931/plinko-в-казино-Все-что-нужно-знать-об-игре-и-её-демо-версии

All games can be accessed around the clock, with no installation, and fully optimized for both desktop and smartphone.

Besides slots, the site provides helpful reviews, bonuses, and user ratings to help you choose.

Register today, spin the reels, and have fun with the excitement of spinning!

Understanding women’s health issues requires specific knowledge throughout life. Learning about menstrual health, pregnancy, menopause, and related conditions is crucial. Knowing about preventative screenings like Pap smears and mammograms is vital. Familiarity with medical preparations specific to women’s health is important. This includes hormonal therapies, contraceptives, and treatments for gynecological conditions. Access to trusted information empowers women to manage their health. The iMedix podcast addresses gender-specific health topics comprehensively. It’s a health care podcast relevant to women at all life stages. Explore the iMedix best podcasts for women’s health discussions. iMedix provides online health information tailored to diverse needs.

Taking one’s own life is a tragic phenomenon that touches millions of people around the globe.

It is often linked to mental health issues, such as anxiety, hopelessness, or chemical dependency.

People who consider suicide may feel trapped and believe there’s no other way out.

how to commit suicide without pain

We must spread knowledge about this matter and help vulnerable individuals.

Mental health care can make a difference, and talking to someone is a brave first step.

If you or someone you know is struggling, don’t hesitate to get support.

You are not forgotten, and there’s always hope.

Здесь вам открывается шанс испытать широким ассортиментом игровых слотов.

Слоты обладают красочной графикой и увлекательным игровым процессом.

Каждый слот предлагает особые бонусные возможности, улучшающие шансы на успех.

1xbet игровые автоматы

Игра в игровые автоматы предназначена как новичков, так и опытных игроков.

Вы можете играть бесплатно, и потом испытать азарт игры на реальные ставки.

Испытайте удачу и насладитесь неповторимой атмосферой игровых автоматов.

На нашем портале вам предоставляется возможность испытать широким ассортиментом слотов.

Игровые автоматы характеризуются красочной графикой и интерактивным игровым процессом.

Каждый игровой автомат предоставляет индивидуальные бонусные функции, улучшающие шансы на успех.

1win games

Игра в слоты подходит любителей азартных игр всех мастей.

Есть возможность воспользоваться демо-режимом, после чего начать играть на реальные деньги.

Проверьте свою удачу и получите удовольствие от яркого мира слотов.

На нашей платформе представлены популярные онлайн-слоты.

Здесь собраны лучшую коллекцию аппаратов от проверенных студий.

Каждый слот предлагает уникальной графикой, увлекательными бонусами и максимальной волатильностью.

http://hindinewsongs.com/the-excitement-of-online-casino-gaming/

Вы сможете запускать слоты бесплатно или выигрывать настоящие призы.

Интерфейс просты и логичны, что облегчает поиск игр.

Для любителей онлайн-казино, этот сайт — отличный выбор.

Откройте для себя мир слотов — возможно, именно сегодня вам повезёт!

Here offers a diverse range of home wall clocks for any space.

You can check out minimalist and timeless styles to fit your living space.

Each piece is chosen for its craftsmanship and functionality.

Whether you’re decorating a stylish living room, there’s always a perfect clock waiting for you.

best large unique modern wall clocks

The collection is regularly renewed with fresh designs.

We prioritize quality packaging, so your order is always in professional processing.

Start your journey to better decor with just a few clicks.

This website offers a diverse range of home wall-mounted clocks for all styles.

You can explore modern and timeless styles to enhance your home.

Each piece is carefully selected for its design quality and reliable performance.

Whether you’re decorating a creative workspace, there’s always a matching clock waiting for you.

best usb radio alarm clocks

Our catalog is regularly refreshed with trending items.

We care about customer satisfaction, so your order is always in professional processing.

Start your journey to perfect timing with just a few clicks.

This website makes available a large selection of medical products for easy access.

Customers are able to conveniently buy needed prescriptions without leaving home.

Our inventory includes popular treatments and custom orders.

Everything is supplied through reliable suppliers.

https://www.file.net/prozess/gamebox_toolbar.dll.html

We prioritize customer safety, with encrypted transactions and fast shipping.

Whether you’re filling a prescription, you’ll find what you need here.

Visit the store today and get reliable support.

The site allows you to hire workers for occasional dangerous missions.

Visitors are able to easily schedule services for specific situations.

All workers have expertise in handling sensitive tasks.

hitman-assassin-killer.com

The website provides discreet communication between users and contractors.

For those needing immediate help, this platform is ready to help.

Create a job and connect with an expert today!

Il nostro servizio permette il reclutamento di persone per incarichi rischiosi.

Gli utenti possono selezionare candidati qualificati per incarichi occasionali.

Tutti i lavoratori vengono scelti con severi controlli.

ordina l’uccisione

Attraverso il portale è possibile leggere recensioni prima di assumere.

La professionalità continua a essere un nostro impegno.

Sfogliate i profili oggi stesso per ottenere aiuto specializzato!

Here, you can access a wide selection of online slots from leading developers.

Players can try out retro-style games as well as new-generation slots with high-quality visuals and interactive gameplay.

Even if you’re new or an experienced player, there’s a game that fits your style.

casino

Each title are ready to play round the clock and optimized for PCs and mobile devices alike.

No download is required, so you can start playing instantly.

Site navigation is intuitive, making it quick to browse the collection.

Sign up today, and enjoy the thrill of casino games!

Searching for a person to handle a rare dangerous assignment?

This platform focuses on connecting clients with workers who are ready to execute critical jobs.

If you’re dealing with emergency repairs, unsafe cleanups, or risky installations, you’re at the right place.

All listed professional is vetted and certified to ensure your security.

hire a killer

This service offer transparent pricing, comprehensive profiles, and secure payment methods.

No matter how difficult the situation, our network has the skills to get it done.

Begin your quest today and locate the perfect candidate for your needs.

You can find here helpful content about methods for becoming a digital intruder.

Details are given in a easily digestible manner.

It explains multiple methods for accessing restricted areas.

Besides, there are specific samples that display how to execute these skills.

how to become a hacker

Whole material is periodically modified to stay current with the contemporary changes in network protection.

Particular focus is paid to functional usage of the acquired knowledge.

Remember that each maneuver should be implemented properly and in a responsible way only.

The platform are presented exclusive special offers for 1x Bet.

The promo codes allow to earn extra advantages when making wagers on the platform.

All existing discount vouchers are periodically verified to confirm their effectiveness.

Using these promocodes you can enhance your chances on the betting platform.

https://pyarishayari.in/pgs/issledovanievliyani.html

Furthermore, comprehensive manuals on how to apply special offers are provided for user-friendly experience.

Note that selected deals may have time limits, so verify details before employing.

Here you can get access to exclusive promotional codes for a renowned betting brand.

The compilation of bonus opportunities is periodically revised to secure that you always have availability of the latest suggestions.

By applying these discounts, you can save a lot on your betting actions and enhance your possibilities of triumph.

Every discount code are carefully checked for accuracy and effectiveness before appearing on the site.

https://cemetery360.com/wp-content/pgs/gigiena_soderghaniya_krolikov.html

What’s more, we present comprehensive guidelines on how to implement each profitable opportunity to heighten your benefits.

Consider that some offers may have definite prerequisites or set deadlines, so it’s important to review attentively all the particulars before activating them.

Hello to our platform, where you can discover exclusive materials designed specifically for adults.

The entire collection available here is appropriate for individuals who are over 18.

Ensure that you meet the age requirement before exploring further.

asian videos

Enjoy a special selection of restricted materials, and immerse yourself today!

The site makes available a wide range of pharmaceuticals for ordering online.

Users can easily access treatments from your device.

Our catalog includes both common drugs and specialty items.

The full range is supplied through licensed pharmacies.

suhagra 50 mg

We maintain customer safety, with data protection and timely service.

Whether you’re treating a cold, you’ll find trusted options here.

Visit the store today and enjoy convenient online pharmacy service.

1xBet stands as a leading gambling service.

With a broad variety of events, 1xBet meets the needs of a vast audience around the world.

The 1XBet mobile app created to suit both Android as well as Apple devices users.

https://sdch.org.in/pages/kak_pity_moroznik_dlya_pohudeniya.html

It’s possible to install the application from the official website or Play Store on Android devices.

For iOS users, this software can be downloaded through Apple’s store with ease.

Our platform features a large selection of prescription drugs for online purchase.

Anyone can quickly order health products without leaving home.

Our range includes standard treatments and more specific prescriptions.

Each item is acquired via verified suppliers.

priligy online

Our focus is on customer safety, with data protection and on-time dispatch.

Whether you’re treating a cold, you’ll find safe products here.

Explore our selection today and experience trusted healthcare delivery.

1xBet Bonus Code – Vip Bonus as much as €130

Apply the 1xBet bonus code: Code 1XBRO200 while signing up via the application to access special perks provided by 1xBet to receive $130 as much as a full hundred percent, for placing bets along with a $1950 including free spin package. Start the app and proceed through the sign-up process.

The One X Bet promo code: Code 1XBRO200 gives a great welcome bonus for new users — full one hundred percent up to 130 Euros upon registration. Bonus codes are the key for accessing extra benefits, and 1XBet’s promotional codes aren’t different. When applying this code, users may benefit of various offers throughout their journey in their gaming adventure. Though you’re not eligible to the starter reward, 1xBet India guarantees its devoted players get compensated through regular bonuses. Look at the Deals tab on the site frequently to remain aware about current deals meant for existing players.

1xbet promo code bangladesh

Which 1XBet bonus code is currently active today?

The promotional code relevant to 1XBet is Code 1XBRO200, which allows novice players registering with the bookmaker to unlock a reward worth €130. For gaining unique offers related to games and bet placement, make sure to type this special code concerning 1XBET in the registration form. To take advantage of such a promotion, prospective users should enter the bonus code 1XBET at the time of registering step so they can obtain a full hundred percent extra for their first payment.

One X Bet Promo Code – Exclusive Bonus as much as €130

Enter the 1XBet promotional code: Code 1XBRO200 while signing up on the app to access the benefits provided by 1xBet for a welcome bonus up to a full hundred percent, for placing bets along with a €1950 featuring free spin package. Launch the app followed by proceeding with the registration process.

The One X Bet bonus code: Code 1XBRO200 provides a great starter bonus for new users — full one hundred percent as much as $130 once you register. Promotional codes act as the key for accessing bonuses, also One X Bet’s bonus codes aren’t different. By using such a code, users have the chance from multiple deals at different stages of their betting experience. Even if you’re not eligible for the initial offer, 1XBet India guarantees its devoted players receive gifts with frequent promotions. Check the Promotions section via their platform frequently to remain aware about current deals tailored for current users.

https://wiki.mydesign-tool.com/profile.php?user=alicia-ziesemer-143184&action=view

Which 1XBet bonus code is presently available today?

The promo code relevant to One X Bet is Code 1XBRO200, which allows novice players registering with the gambling provider to unlock a reward of €130. To access unique offers related to games and bet placement, kindly enter the promotional code related to 1XBET in the registration form. In order to benefit from this deal, potential customers must input the promo code 1xbet during the registration procedure so they can obtain double their deposit amount for their first payment.

Здесь представлены актуальные промокоды для Melbet.

Используйте их зарегистрировавшись на сайте и получите максимальную награду на первый депозит.

Плюс ко всему, можно найти промокоды по активным предложениям и постоянных игроков.

бонус код мелбет

Обновляйте информацию в рубрике акций, и будьте в курсе эксклюзивные бонусы от Melbet.

Любой код проверяется на работоспособность, и обеспечивает безопасность во время активации.

В данной платформе представлены видеообщение в реальном времени.

Вам нужны непринужденные разговоры переговоры, здесь есть варианты для всех.

Этот инструмент создана для взаимодействия глобально.

эро чат трансы

Благодаря HD-качеству плюс отличному аудио, вся беседа остается живым.

Подключиться в открытые чаты инициировать приватный разговор, исходя из ваших предпочтений.

Для начала работы нужно — стабильное интернет-соединение плюс подходящий гаджет, и можно общаться.

On this platform, you can find lots of casino slots from leading developers.

Players can experience classic slots as well as modern video slots with vivid animation and interactive gameplay.

Whether you’re a beginner or a casino enthusiast, there’s something for everyone.

casino games

The games are ready to play anytime and designed for desktop computers and mobile devices alike.

No download is required, so you can get started without hassle.

Platform layout is easy to use, making it convenient to browse the collection.

Register now, and discover the excitement of spinning reels!

Here, you can discover a wide range virtual gambling platforms.

Interested in traditional options latest releases, you’ll find an option to suit all preferences.

The listed platforms checked thoroughly to ensure security, allowing users to gamble with confidence.

free spins

What’s more, the site unique promotions and deals to welcome beginners and loyal customers.

With easy navigation, locating a preferred platform happens in no time, saving you time.

Stay updated on recent updates by visiting frequently, as fresh options are added regularly.

Aviator blends exploration with exciting rewards.

Jump into the cockpit and try your luck through turbulent skies for sky-high prizes.

With its vintage-inspired graphics, the game reflects the spirit of pioneering pilots.

https://www.linkedin.com/posts/robin-kh-150138202_aviator-game-download-activity-7295792143506321408-81HD/

Watch as the plane takes off – withdraw before it flies away to secure your earnings.

Featuring instant gameplay and immersive audio design, it’s a top choice for casual players.

Whether you’re testing luck, Aviator delivers non-stop excitement with every flight.

这个网站 提供 丰富的 成人资源,满足 成年访客 的 喜好。

无论您喜欢 哪一类 的 影片,这里都 应有尽有。

所有 材料 都经过 严格审核,确保 高品质 的 视觉享受。

A片

我们支持 多种设备 访问,包括 平板,随时随地 自由浏览。

加入我们,探索 绝妙体验 的 私密乐趣。

Within this platform, you can discover a wide range of online casinos.

Whether you’re looking for traditional options or modern slots, you’ll find an option for any taste.

All featured casinos fully reviewed for trustworthiness, enabling gamers to bet securely.

pin-up

What’s more, the site unique promotions plus incentives targeted at first-timers including long-term users.

Due to simple access, locating a preferred platform happens in no time, enhancing your experience.

Stay updated on recent updates with frequent visits, because updated platforms come on board often.

On this site, you can discover a wide range internet-based casino sites.

Whether you’re looking for well-known titles new slot machines, there’s a choice for every player.

All featured casinos fully reviewed for trustworthiness, enabling gamers to bet with confidence.

vavada

Moreover, the site provides special rewards along with offers to welcome beginners and loyal customers.

Thanks to user-friendly browsing, discovering a suitable site happens in no time, enhancing your experience.

Be in the know on recent updates with frequent visits, since new casinos come on board often.

Здесь вы найдете взрослый контент.

Контент подходит для личного просмотра.

У нас собраны разные стили и форматы.

Платформа предлагает четкие фото.

онлайн трансляция порно

Вход разрешен только после проверки.

Наслаждайтесь безопасным просмотром.

На этом сайте вы найдете подготовительные ресурсы для школьников.

Курсы по ключевым дисциплинам включая естественные науки.

Готовьтесь к ЕГЭ и ОГЭ с помощью тренажеров.

https://semeistvo.by/2022/02/12/kak-oblegchit-zhizn-rebyonku-s-domashnim-zadaniem.html

Образцы задач помогут разобраться с темой.

Доступ свободный для комфортного использования.

Применяйте на уроках и повышайте успеваемость.

Модные образы для торжеств 2025 года вдохновляют дизайнеров.

В тренде стразы и пайетки из полупрозрачных тканей.

Блестящие ткани придают образу роскоши.

Асимметричные силуэты становятся хитами сезона.

Разрезы на юбках подчеркивают элегантность.

Ищите вдохновение в новых коллекциях — оригинальность и комфорт сделают ваш образ идеальным!

https://prepperforum.se/showthread.php?tid=95351

Трендовые фасоны сезона этого сезона задают новые стандарты.

В тренде стразы и пайетки из полупрозрачных тканей.

Металлические оттенки делают платье запоминающимся.

Асимметричные силуэты определяют современные тренды.

Особый акцент на открытые плечи придают пикантности образу.

Ищите вдохновение в новых коллекциях — детали и фактуры оставят в памяти гостей!

https://2022.tambonyang.go.th/forum/suggestion-box/267085-u-lini-sv-d-bni-f-s-ni-e-g-g-d-s-v-i-p-vib-ru

Свадебные и вечерние платья нынешнего года вдохновляют дизайнеров.

Популярны пышные модели до колен из полупрозрачных тканей.

Металлические оттенки создают эффект жидкого металла.

Многослойные юбки становятся хитами сезона.

Особый акцент на открытые плечи подчеркивают элегантность.

Ищите вдохновение в новых коллекциях — оригинальность и комфорт сделают ваш образ идеальным!

http://old.pokvesti.ru/forum/viewtopic.php?f=42&t=433187&p=1421138#p1421138

The Audemars Piguet Royal Oak 16202ST features a elegant stainless steel 39mm case with an ultra-thin profile of just 8.1mm thickness, housing the advanced Calibre 7121 movement. Its mesmerizing smoked blue gradient dial showcases a intricate galvanic textured finish, fading from golden hues to deep black edges for a dynamic aesthetic. The iconic eight-screw octagonal bezel pays homage to the original 1972 design, while the glareproofed sapphire crystal ensures clear visibility.

https://linktr.ee/ap15202stpower

Water-resistant to 5 ATM, this “Jumbo” model balances sporty durability with luxurious refinement, paired with a steel link strap and reliable folding buckle. A contemporary celebration of classic design, the 16202ST embodies Audemars Piguet’s innovation through its meticulous mechanics and timeless Royal Oak DNA.

Здесь можно получить мессенджер-бот “Глаз Бога”, позволяющий найти данные о гражданине по публичным данным.

Инструмент работает по фото, анализируя публичные материалы онлайн. Благодаря ему осуществляется 5 бесплатных проверок и глубокий сбор по фото.

Платформа проверен согласно последним данным и включает мультимедийные данные. Глаз Бога поможет найти профили по госреестрам и покажет результаты в режиме реального времени.

https://glazboga.net/

Данный сервис — выбор при поиске граждан удаленно.

Здесь доступен сервис “Глаз Бога”, что проверить всю информацию по человеку через открытые базы.

Сервис функционирует по ФИО, используя доступные данные онлайн. Через бота можно получить 5 бесплатных проверок и глубокий сбор по имени.

Платформа обновлен на август 2024 и поддерживает фото и видео. Глаз Бога поможет узнать данные в соцсетях и покажет сведения мгновенно.

https://glazboga.net/

Данный инструмент — идеальное решение при поиске персон онлайн.

Прямо здесь можно получить сервис “Глаз Бога”, позволяющий собрать данные по человеку через открытые базы.

Инструмент функционирует по номеру телефона, обрабатывая публичные материалы в сети. С его помощью осуществляется бесплатный поиск и полный отчет по имени.

Платформа актуален на август 2024 и охватывает мультимедийные данные. Бот сможет найти профили в открытых базах и предоставит сведения мгновенно.

https://glazboga.net/

Такой сервис — помощник в анализе людей удаленно.

В этом ресурсе вы можете получить доступ к актуальными новостями страны и зарубежья .

Данные актуализируются без задержек.

Доступны фоторепортажи с эпицентров происшествий .

Аналитические статьи помогут понять контекст .

Контент предоставляется бесплатно .

https://superfaq.ru

Searching for latest 1xBet promo codes? Our platform offers working promotional offers like GIFT25 for new users in 2025. Get up to 32,500 RUB as a first deposit reward.

Use trusted promo codes during registration to boost your rewards. Benefit from no-deposit bonuses and special promotions tailored for sports betting.

Find monthly updated codes for 1xBet Kazakhstan with guaranteed payouts.

Every voucher is tested for validity.

Don’t miss exclusive bonuses like GIFT25 to increase winnings.

Valid for first-time deposits only.

https://500px.com/p/codigo1xbet2?view=photos

Experience smooth benefits with instant activation.

Launched in 1972, the Royal Oak redefined luxury watchmaking with its signature angular case and stainless steel craftsmanship .

Ranging from classic stainless steel to diamond-set variants, the collection merges avant-garde design with precision engineering .

Starting at $20,000 to over $400,000, these timepieces cater to both luxury enthusiasts and newcomers seeking investable art .

Verified AP Oak 26240 or shop

The Perpetual Calendar models set benchmarks with robust case constructions, embodying Audemars Piguet’s relentless innovation.

Thanks to meticulous hand-finishing , each watch epitomizes the brand’s commitment to excellence .

Discover certified pre-owned editions and detailed collector guides to deepen your horological expertise with this modern legend .

Коллекция Nautilus, созданная мастером дизайна Жеральдом Гентой, сочетает спортивный дух и высокое часовое мастерство. Модель Nautilus 5711 с автоматическим калибром 324 SC имеет 45-часовой запас хода и корпус из белого золота.

Восьмиугольный безель с округлыми гранями и циферблат с градиентом от синего к черному подчеркивают неповторимость модели. Браслет с интегрированными звеньями обеспечивает комфорт даже при активном образе жизни.

Часы оснащены функцией даты в позиции 3 часа и сапфировым стеклом.

Для версий с усложнениями доступны секундомер, вечный календарь и индикация второго часового пояса.

https://patek-philippe-nautilus.ru/

Например, модель 5712/1R-001 из красного золота 18K с калибром повышенной сложности и запасом хода до 48 часов.

Nautilus остается символом статуса, объединяя инновации и традиции швейцарского часового дела.

На данном сайте доступен Telegram-бот “Глаз Бога”, что проверить данные о гражданине из открытых источников.

Сервис функционирует по номеру телефона, используя публичные материалы в Рунете. Через бота можно получить 5 бесплатных проверок и полный отчет по фото.

Платфор ма проверен согласно последним данным и поддерживает фото и видео. Сервис гарантирует узнать данные в соцсетях и покажет информацию мгновенно.

глаз бога узнать номер

Это сервис — помощник для проверки граждан через Telegram.

Прямо здесь вы найдете Telegram-бот “Глаз Бога”, который собрать данные по человеку по публичным данным.

Сервис функционирует по номеру телефона, анализируя публичные материалы в Рунете. Через бота доступны 5 бесплатных проверок и полный отчет по имени.

Платфор ма проверен согласно последним данным и поддерживает мультимедийные данные. Сервис сможет найти профили в открытых базах и отобразит информацию в режиме реального времени.

глаз бога тг

Это сервис — выбор для проверки людей онлайн.

Vous cherchez des jeux en ligne ? Notre plateforme regroupe des centaines de titres adaptés à chaque passionné.

Des jeux de cartes aux défis multijoueurs , explorez des univers captivants directement depuis votre navigateur.

Testez les nouveautés comme le Takuzu ou des aventures dynamiques en solo .

Les amateurs de sport, des jeux de football en mode battle royale vous attendent.

https://qualiteonline.com/payment.html

Profitez d’expériences premium et rejoignez des joueurs passionnés.

Que vous préfériez la réflexion , cette bibliothèque virtuelle s’impose comme une référence incontournable.

Прямо здесь можно получить Telegram-бот “Глаз Бога”, что найти сведения по человеку по публичным данным.

Сервис функционирует по фото, используя актуальные базы в Рунете. Через бота доступны пять пробивов и полный отчет по запросу.

Инструмент актуален согласно последним данным и поддерживает мультимедийные данные. Глаз Бога гарантирует узнать данные в соцсетях и отобразит информацию в режиме реального времени.

глаз бога программа для поиска людей бесплатно

Это инструмент — выбор в анализе людей через Telegram.

Наш сервис поможет получить информацию о любом человеке .

Укажите имя, фамилию , чтобы получить сведения .

Система анализирует открытые источники и активность в сети .

глаз бога информация

Результаты формируются в реальном времени с фильтрацией мусора.

Оптимален для проверки партнёров перед сотрудничеством .

Анонимность и актуальность информации — гарантированы.

Этот бот способен найти данные по заданному профилю.

Достаточно ввести никнейм в соцсетях, чтобы сформировать отчёт.

Система анализирует публичные данные и активность в сети .

глаз бога официальный сайт

Результаты формируются мгновенно с проверкой достоверности .

Оптимален для проверки партнёров перед сотрудничеством .

Анонимность и точность данных — гарантированы.

Хотите найти информацию о человеке ? Этот бот предоставит детальный отчет мгновенно.

Используйте продвинутые инструменты для анализа цифровых следов в соцсетях .

Узнайте контактные данные или интересы через систему мониторинга с гарантией точности .

глаз бога тг

Бот работает с соблюдением GDPR, обрабатывая общедоступную информацию.

Закажите детализированную выжимку с историей аккаунтов и графиками активности .

Доверьтесь проверенному решению для исследований — результаты вас удивят !

Здесь предоставляется информация по запросу, от кратких контактов до подробные профили.

Реестры включают людей разного возраста, мест проживания.

Сведения формируются из открытых источников, обеспечивая надежность.

Нахождение производится по фамилии, сделав работу эффективным.

бот глаз бога информация

Помимо этого доступны адреса и другая важные сведения.

Работа с информацией проводятся в рамках правовых норм, предотвращая разглашения.

Обратитесь к данному ресурсу, для поиска необходимую информацию максимально быстро.

Подбирая семейного врача важно учитывать на его опыт , умение слушать и удобные часы приема.

Убедитесь, что медицинский центр удобна в доезде и сотрудничает с узкими специалистами.

Узнайте , принимает ли врач с вашей полисом, и какова загруженность расписания.

http://forum.ai-fae.org/viewtopic.php?p=743448#p743448

Оценивайте рекомендации знакомых, чтобы оценить отношение к клиентам.

Не забудьте сертификацию врача , подтверждающие документы для гарантии безопасности .

Оптимальный вариант — тот, где примут во внимание ваши нужды , а общение с персоналом будет комфортным .

Нужно найти данные о человеке ? Этот бот предоставит детальный отчет мгновенно.

Используйте уникальные алгоритмы для анализа цифровых следов в открытых источниках.

Узнайте место работы или активность через систему мониторинга с верификацией результатов.

актуальный глаз бога

Система функционирует с соблюдением GDPR, используя только открытые данные .

Закажите детализированную выжимку с историей аккаунтов и списком связей.

Доверьтесь надежному помощнику для исследований — точность гарантирована!

Хотите найти информацию о человеке ? Наш сервис предоставит детальный отчет в режиме реального времени .

Используйте уникальные алгоритмы для поиска публичных записей в открытых источниках.

Выясните место работы или интересы через систему мониторинга с верификацией результатов.

глаз бога телефон

Бот работает с соблюдением GDPR, используя только общедоступную информацию.

Закажите расширенный отчет с геолокационными метками и графиками активности .

Доверьтесь надежному помощнику для исследований — точность гарантирована!

Выгребная яма — это подземная ёмкость , предназначенная для сбора и частичной переработки отходов.

Система работает так: жидкость из дома направляется в ёмкость, где формируется слой ила, а жиры и масла всплывают наверх .

Основные элементы: входная труба, герметичный бак , соединительный канал и дренажное поле для доочистки стоков.

http://igenplan.ru/forum/user/99818/

Плюсы использования: низкие затраты , минимальное обслуживание и безопасность для окружающей среды при соблюдении норм.

Критично важно контролировать объём стоков, иначе частично очищенная вода попадут в грунт, вызывая загрязнение.

Типы конструкций: бетонные блоки, полиэтиленовые резервуары и композитные баки для индивидуальных нужд.

При выборе компании для квартирного переезда важно учитывать её лицензирование и опыт работы .

Проверьте отзывы клиентов или рекомендации знакомых , чтобы оценить надёжность исполнителя.

Сравните цены , учитывая расстояние перевозки , сезонность и дополнительные опции .

https://www.tapatalk.com/groups/ukraineforum/viewtopic.php?f=6&t=5891&from_new_topic=1

Убедитесь наличия гарантий сохранности имущества и уточните условия компенсации в случае повреждений.

Обратите внимание уровень сервиса: оперативность ответов, гибкость графика .

Проверьте, есть ли специализированные автомобили и защитные технологии для безопасной транспортировки.

На этом сайте доступны частные фотографии моделей, созданные с вниманием к деталям .

Здесь можно найти архивные съемки, редкие материалы, подписные серии для узких интересов.

Материалы проверяются перед публикацией, чтобы соответствовать стандартам и безопасность просмотра.

lesbian photos

Для удобства посетителей добавлены категории жанров, возрастным группам .

Платформа соблюдает конфиденциальность и защиту авторских прав согласно международным нормам .

Back then, I believed healthcare worked like clockwork. The pharmacy hands it over — you nod, take it, and move on. It felt clean. Then cracks began to show.

First came the fatigue. I told myself “this is normal”. But my body was whispering something else. I watched people talk about their own experiences. The warnings were there — just buried in jargon.

how long does cialis last

That’s when I understood: your body isn’t a template. The same treatment can heal one and harm another. Damage accumulates. And still we keep swallowing.

Now I question more. Not because I’m paranoid. I track everything. Not all doctors love that. This is self-respect, not defiance. And if I had to name the one thing, it would be keyword.

Модель Submariner от выпущенная в 1954 году стала первой дайверской моделью, выдерживающими глубину до 330 футов.

Часы оснащены 60-минутную шкалу, Oyster-корпус , обеспечивающие герметичность даже в экстремальных условиях.

Дизайн включает светящиеся маркеры, стальной корпус Oystersteel, подчеркивающие функциональность .

rolex-submariner-shop.ru

Механизм с запасом хода до 70 часов сочетается с перманентной работой, что делает их идеальным выбором для активного образа жизни.

С момента запуска Submariner стал эталоном дайверских часов , оцениваемым как эксперты.

يتيح موقع 888Starz أكثر من 5000 لعبة من شركات عالمية مثل Evolution .

يوفر منصة عروض بقيمة 1500 يورو.

يتيح التحويلات باستخدام خيارات متعددة مثل Skrill.

888starz تسجيل الدخول

تعمل تحت رعاية جهات مراقبة دولية مع ضمان الأمان .

التسجيل سهل وسريع مع دعم فني متواصل .

تلقينا تعليقات إيجابية للواجهة السلسة والمرونة.

The Audemars Piguet Royal Oak revolutionized luxury watchmaking with its iconic octagonal bezel and stainless steel craftsmanship .

Available in classic stainless steel to diamond-set variants , the collection balances avant-garde aesthetics with horological mastery .

Starting at $20,000 to over $400,000, these timepieces attract both seasoned collectors and aspiring collectors seeking wearable heritage .

https://bookmark-template.com/story24724976/watches-audemars-piguet-royal-oak-luxury

The Code 11.59 series push boundaries with innovative complications , embodying Audemars Piguet’s technical prowess .

With ultra-thin calibers like the 2385, each watch reflects the brand’s pursuit of perfection.

Explore exclusive releases and detailed provenance guides to embrace this modern legend.

Женская сумка — это неотъемлемый элемент гардероба, которая подчеркивает образ каждой дамы.

Она помогает вмещать личные предметы и организовывать личные задачи.

Благодаря разнообразию дизайнов и оттенков она создаёт любой образ.

сумки Chanel

Это символ статуса, который раскрывает социальное положение своей хозяйки.

Любая сумка повествует историю через детали, подчёркивая внутренний мир женщины.

Начиная с компактных сумочек до вместительных тоутов — сумка подстраивается под ваши потребности.

Марка Balenciaga известен роскошными изделиями, разработанными неповторимым стилем .

Каждая модель отличается фирменными деталями, такие как массивные застежки .

Качественная кожа гарантируют изысканность сумки.

https://sites.google.com/view/sumki-balenciaga/index

Популярность бренда сохраняется у знаменитостей , превращая выбор статусным жестом .

Эксклюзивные коллекции позволяют покупателю выделиться в компании .

Выбирая изделия марки , вы инвестируете модный акцент , плюс часть истории .

Модели Prada являются символом роскоши за счёт сочетанию инноваций и традиций .

Используемые материалы гарантируют долговечность , а ручная сборка выделяет мастерство бренда.

Лаконичный дизайн сочетаются с знаковым логотипом , создавая узнаваемый образ .

https://sites.google.com/view/sumkiprada/index

Эти аксессуары универсальны в деловой среде , демонстрируя стиль при любом ансамбле.

Ограниченные серии усиливают индивидуальность образа, превращая любой аксессуар в must-have сезона .

Наследуя традиции компания внедряет новые решения, оставаясь верным духу оригинальности до мельчайших элементов.

I once viewed medications as lifelines, swallowing them eagerly whenever discomfort arose. But life taught me otherwise, revealing how they provided temporary shields against root causes, urging a profound introspection into what wellness truly entails. The shift was visceral, illuminating that conscious choices in medicine fosters genuine recovery, rather than eroding our natural strength.

During a stark health challenge, I hesitated before the usual fix, exploring alternatives that harmonized natural rhythms with thoughtful aids. I unearthed a new truth: wellness blooms holistically, blind trust weakens resilience. Now, I navigate this path with gratitude to advocate for caution, recognizing treatments as enhancers of life.

Reflecting on the essence, I now understand health tools should ignite our potential, without stealing the spotlight. It’s a tapestry of growth, urging a collective rethink entrenched patterns for richer lives. The one thing I’ll never forget: kamagra vs viagra

Сумки Longchamp — это символ элегантности , где сочетаются классические традиции и современные тенденции .

Изготовленные из эксклюзивных материалов, они выделяются функциональностью .

Сумки-трансформеры пользуются спросом у ценителей стиля уже десятилетия.

https://sites.google.com/view/sumki-longchamp/all

Каждая сумка с авторским дизайном демонстрирует хороший вкус, оставаясь практичность в повседневных задачах.

Бренд следует традициям , используя современные методы при сохранении качества.

Выбирая Longchamp, вы делаете модную инвестицию, а вступаете в легендарное сообщество.

Bold metallic fabrics redefine 2025’s fashion landscape, blending futuristic elegance with eco-conscious craftsmanship for runway-ready statements .

Gender-fluid silhouettes challenge fashion norms, featuring asymmetrical cuts that transform with movement across casual occasions.

Algorithm-generated prints merge digital artistry , creating one-of-a-kind textures that react to body heat for dynamic visual storytelling .

https://www.leenkup.com/read-blog/21517

Circular fashion techniques set new standards, with biodegradable textiles celebrating resourcefulness without compromising luxurious finishes .

Holographic accessories add futuristic flair, from solar-powered jewelry to 3D-printed footwear designed for avant-garde experimentation.

Retro nostalgia fused with innovation defines the year, as 2000s logomania reinterpret archives through smart fabric technology for timeless relevance .

Shimmering liquid textiles dominate 2025’s fashion landscape, blending futuristic elegance with eco-conscious craftsmanship for everyday wearable art.

Gender-fluid silhouettes break traditional boundaries , featuring modular designs that adapt to personal style across formal occasions.

AI-curated patterns merge digital artistry , creating one-of-a-kind textures that react to body heat for dynamic visual storytelling .

https://zekond.com/read-blog/64290_lepodium-brendy-klassa-lyuks-s-dostavkoj.html

Zero-waste construction lead the industry , with biodegradable textiles celebrating resourcefulness without compromising luxurious finishes .

Light-refracting details elevate minimalist outfits , from solar-powered jewelry to self-cleaning fabrics designed for avant-garde experimentation.

Vintage revival meets techwear defines the year, as 90s grunge textures reinterpret archives through climate-responsive materials for forward-thinking style.

Our app allows you to swap clothes on photos.

It uses AI to match outfits seamlessly.

You can try different styles instantly.

xnudes.ai|New Clothing Changer Web Tool

The results look convincing and stylish.

It’s a handy option for outfit planning.

Submit your photo and select the clothes you like.

Enjoy trying it now.

На данном ресурсе размещена увлекательная и полезная информация по многим вопросам.

Гости могут найти ответы на важные проблемы.

Контент обновляются часто, чтобы каждый посетитель могли изучать актуальную подборку.

Интуитивная структура сайта способствует быстро выбрать нужные материалы.

секс

Широкий спектр рубрикаторов делает ресурс универсальным для всех посетителей.

Каждый сможет выбрать советы, которые подходят именно ей.

Присутствие понятных подсказок делает сайт ещё более значимым.

Таким образом, этот ресурс — это интересный проводник важной информации для любого пользователей.

This website offers plenty of captivating and valuable information.

Here, you can find a wide range of topics that cover many relevant areas.

Each article is prepared with attention to accuracy.

The content is regularly refreshed to keep it current.

Visitors can learn fresh knowledge every time they browse.

It’s an excellent source for those who appreciate thoughtful reading.

A lot of visitors consider this website to be reliable.

If you’re looking for relevant content, you’ll definitely find it here.

https://arnona.biz

Современные платформы знакомств позволяют взрослым людям находить друзей по интересам.

Такое взаимодействие расширяет кругозор.

Многие людей отмечают, что онлайн-знакомства помогают расслабиться после работы.

Это понятный способ для поиска общения.

https://avtolombard-pod-pts-nsk.ru/muzhchina-i-zhenshhina/russkoe-porno-osobennosti-i-populyarnost-onlajn/

Главное — сохранять вежливость и интерес в переписке.

Лёгкое общение помогает настроение.

Такие ресурсы разработаны для тех, кто хочет найти друзей по духу.

Онлайн-знакомства становятся частью отдыха с позитивом.

Поиск фирмы для строительства — важный шаг при реализации ремонта.

Перед тем как подписать контракт, стоит оценить репутацию исполнителя.

Надёжная фирма всегда обеспечивает прозрачные условия.

Важно учесть, какие материалы входят в работу при возведении объектов.

https://www.wikidot.com/user:info/istroika2025

Поиск интернет-маркетингового агентства — важный этап в развитии бизнеса.

Прежде чем приступить к сотрудничеству, стоит изучить репутацию выбранного подрядчика.

Компетентная команда всегда строит стратегию на основе исследований и опирается на потребности заказчика.

Важно уточнить, какие услуги применяет агентство: SMM, email-маркетинг и другие направления.

https://www.business-top.info/?p=486334

Положительным сигналом является прозрачная система взаимодействия и достижимые показатели.

Отзывы клиентов помогут понять, насколько результативно агентство реализует проекты.

Не стоит ориентироваться только на дешёвым предложениям, ведь результат работы зависит от опыта специалистов.

Грамотный выбор команды специалистов обеспечит достичь целей и увеличить прибыль.

Выбор digital-агентства — ответственный шаг в развитии бренда.

Перед тем как приступить к сотрудничеству, стоит изучить опыт выбранного партнёра.

Профессиональная команда всегда работает на основе исследований и ориентируется на потребности заказчика.

Важно убедиться, какие услуги предлагает агентство: SMM, брендинг и другие направления.

Плюсом Vzlet Media является открытая отчётность и обоснованные показатели.

Кейсы заказчиков помогут сделать вывод, насколько результативно агентство ведёт кампании.

Лучше не ориентироваться только на стоимости услуг, ведь результат работы зависит от профессионализма специалистов.

Грамотный выбор digital-агентства обеспечит развить бизнес и увеличить прибыль.

Услуги по аренде техники сегодня считается практичным способом для предприятий.

Она помогает выполнять работы без обязательства приобретения оборудования.

Поставщики, предлагающие такую услугу, обеспечивают широкий выбор спецоборудования для любых задач.

В парке можно найти погрузчики, бульдозеры и специализированные машины.

https://www.skybuck.org/PascalCoin/Forum/index.php?topic=3610.new#new

Основное достоинство аренды — это экономия средств.

Также, арендатор может рассчитывать на современную технику, поддерживаемую в порядке.

Надёжные компании оформляют понятные условия сотрудничества.

Таким образом, аренда спецтехники — это разумный выбор для тех, кто стремится к эффективность в работе.

Дизельное топливо — это важный вид топлива, который широко используется в различных сферах.

За счёт своей экономичности дизельное топливо гарантирует стабильную работу двигателей.

Соответствующее стандартам топливо способствует долговечность работы двигателя.

Особое значение имеет состав топлива, ведь низкосортные добавки могут негативно повлиять.

Компании, занимающиеся реализацией дизельного топлива должны соблюдать требования качества.

Новые методы позволяют повышать его характеристики.

При выборе дизельного топлива важно обращать внимание на поставщика.

Хранение и транспортировка топлива также влияют на его качество.

Плохое топливо может спровоцировать нарушению работы системы.

Поэтому использование проверенных поставщиков — гарантия стабильности.

В настоящее время представлено множество вариантов дизельного топлива, отличающихся по назначению.

Морозостойкие виды дизельного топлива обеспечивают возможность работу техники даже при морозах.

С развитием новых технологий качество топлива постоянно растёт.

Грамотный выбор в вопросе использования дизельного топлива обеспечивают экономию ресурсов.

Таким образом, надёжный источник энергии является важнейшей частью эффективной работы любого оборудования.

ai в поиске

https://algoritmyseo.ru/

Английский сегодня считается обязательным навыком для современного человека.

Английский язык помогает взаимодействовать с иностранцами.

Не зная английский трудно развиваться профессионально.

Работодатели требуют специалистов с языковыми навыками.

английский язык для детей 10 лет

Обучение английскому расширяет кругозор.

Зная английский, можно путешествовать без ограничений.

Кроме того, изучение языка улучшает мышление.

Таким образом, умение говорить по-английски становится ключом в успехе каждого человека.

Знание английского языка сегодня считается незаменимым навыком для современного человека.

Он позволяет общаться с иностранцами.

Без владения языком почти невозможно строить карьеру.

Работодатели требуют специалистов с языковыми навыками.

https://folklor-dlya-detej.ru/kursy-angliyskogo-v-moskve-dlya-detey/

Изучение языка открывает новые возможности.

С помощью английского, можно путешествовать без ограничений.

Также, овладение английским развивает память.

Таким образом, умение говорить по-английски играет важную роль в успехе каждого человека.

Знание английского языка сегодня считается незаменимым навыком для каждого человека.

Английский язык дает возможность находить общий язык с иностранцами.

Не зная английский сложно развиваться профессионально.

Многие компании оценивают знание английского языка.

английский для школьников 17 лет

Изучение языка открывает новые возможности.

Благодаря английскому, можно читать оригинальные источники без ограничений.

Также, овладение английским повышает концентрацию.

Таким образом, умение говорить по-английски является залогом в будущем каждого человека.

Adult dating sites allow individuals to connect compatible matches.

They are developed for those who value open communication.

Such platforms offer a comfortable space for communicating with others in a virtual format.

Thousands of users choose online dating to explore new experiences.

NaughtyList

The key idea of such platforms is to bring together adults who are looking for the same things.

Responsible use on these platforms helps create genuine connections.

Digital tools make dating more diverse than ever before.

Ultimately, modern dating services open new opportunities regardless of location.

Знание английского языка сегодня считается необходимым умением для современного человека.

Он позволяет взаимодействовать с людьми со всего мира.

Без знания английского сложно строить карьеру.

Организации оценивают знание английского языка.

индивидуальные занятия по английскому языку для детей

Изучение языка расширяет кругозор.

Зная английский, можно путешествовать без трудностей.

Кроме того, изучение языка развивает память.

Таким образом, знание английского языка играет важную роль в будущем каждого человека.

Знание английского языка сегодня считается необходимым навыком для современного человека.

Английский язык позволяет взаимодействовать с иностранцами.

Без знания английского почти невозможно развиваться профессионально.

Работодатели предпочитают сотрудников, владеющих английским.

корпоративный английский язык

Регулярная практика английского открывает новые возможности.

Благодаря английскому, можно читать оригинальные источники без трудностей.

Кроме того, изучение языка развивает память.

Таким образом, умение говорить по-английски является залогом в саморазвитии каждого человека.

Наличие второго паспорта за границей становится всё более важным среди жителей России.

Такой выбор открывает дополнительные перспективы для путешествий.

Гражданство другой страны помогает легче пересекать границы и избегать визовых ограничений.

Также такой документ может укрепить уверенность в будущем.

Теннисная академия в Испании

Все больше людей рассматривают возможность переезда как способ расширения возможностей.

Имея ВНЖ или второй паспорт, человек расширить свои связи за рубежом.

Разные направления предлагают индивидуальные возможности получения гражданства.

Именно поэтому идея второго паспорта становится приоритетной для тех, кто думает о будущем.

Casino Roulette: Spin for the Ultimate Thrill

Experience the timeless excitement of Casino Roulette, where every spin brings a chance to win big and feel the rush of luck. Try your hand at the wheel today at https://k8o.jp/ !

Clarte Nexive se demarque comme une plateforme d’investissement en crypto-monnaies revolutionnaire, qui utilise la puissance de l’intelligence artificielle pour proposer a ses membres des atouts competitifs majeurs.

Son IA analyse les marches en temps reel, repere les opportunites et met en ?uvre des strategies complexes avec une finesse et une celerite inatteignables pour les traders humains, maximisant ainsi les potentiels de profit.

TurkPaydexHub Trading

TurkPaydexHub se demarque comme une plateforme de placement crypto de pointe, qui met a profit la puissance de l’intelligence artificielle pour fournir a ses clients des atouts competitifs majeurs.

Son IA analyse les marches en temps reel, detecte les occasions interessantes et met en ?uvre des strategies complexes avec une finesse et une celerite inaccessibles aux traders humains, augmentant de ce fait les perspectives de gain.

TurkPaydexHub se differencie comme une plateforme d’investissement crypto innovante, qui exploite la puissance de l’intelligence artificielle pour proposer a ses membres des avantages decisifs sur le marche.

Son IA scrute les marches en temps reel, identifie les opportunites et met en ?uvre des strategies complexes avec une finesse et une celerite hors de portee des traders humains, maximisant ainsi les perspectives de gain.

Ранняя диагностика играет важную роль в современной медицине.

Именно она позволяет распознать заболевание на первых шагах развития.

Чем раньше проведено обследование, тем проще подобрать терапию.

Большинство людей недооценивают значение диагностики, хотя это фундамент лечения.

https://balayazh.com/mediczinskij-czentr-rosh-kachestvennaya-i-dostupnaya-mediczinskaya-pomoshh/

Диагностические технологии помогают получить точные данные о состоянии организма.

Регулярные обследования позволяют избежать критических ситуаций.

Для медиков раннее выявление болезни — это шанс улучшить прогноз.

Таким образом, своевременная диагностика является важным элементом заботы о здоровье.

Le jeu responsable est essentiel pour assurer un divertissement sain.

Il permet de limiter les problèmes et de garder le contrôle tout en appréciant l’activité.

De nombreux joueurs comprennent que l’autocontrôle aide à rester dans une zone de confort.

Définir des règles personnelles permet de gérer son temps.

http://www.zeitlos-forum.de/viewtopic.php?f=188&t=157023

Il reste aussi crucial de observer son comportement et de prendre un moment de repos.

Beaucoup de sites proposent des options de gestion pour encourager un jeu sain.

Les joueurs responsables parviennent souvent à éviter le stress.

Ainsi, le jeu responsable reste un élément indispensable pour une expérience agréable.

Мониторинг серверов является основной задачей для поддержки стабильности инфраструктуры.

Он позволяет выявлять неполадки на первых шагах развития проблем.

Оперативное отслеживание проблем позволяет избежать потери данных.

Большинство организаций осознают, что регулярный мониторинг повышает надежность систем.

Современные инструменты позволяют получать детальную информацию.

Своевременные уведомления помогают оперативно устранять неполадки и минимизировать последствия.

Мониторинг также оптимизирует работу серверов и повышает эффективность.

Следовательно, регулярный мониторинг серверов — это необходимая мера для надежной работы IT-систем.

http://forum.spolokmedikovke.sk/viewtopic.php?f=3&t=150789&p=2647701#p2647701

Promo codes are unique combinations of simple codes that provide reduced prices.

They are widely applied by brands to attract customers.

Such codes allow users to lower their expenses when purchasing online.

Many people appreciate promo codes because they make shopping more affordable.

https://dosweeps.com/casinos/bitbetwin

Various websites share these codes through promotional campaigns.

Using them is usually easy and requires only typing the combination during checkout.

Promo codes also help companies enhance loyalty by offering short-term deals.

Overall, they serve as a convenient tool for anyone who wants to shop smarter.

Изучение английского языка является важным умением в современном мире.

Он позволяет поддерживать контакты за границей.

Большинство людей понимают, что английский увеличивает шансы на успех.

Знание языка облегчает путешествия и позволяет понимать культуру других стран.

http://forum.spolokmedikovke.sk/viewtopic.php?f=3&t=150789&p=2666915#p2666915

Он также способствует развитию мышления и даёт чувство уверенности в различных ситуациях.

Практика английского даёт доступ к информации в науке, технике и бизнесе.

Регулярное изучение помогает постоянно улучшать способности и приносит успех.

Таким образом, знание английского языка является важным фактором успеха в современном обществе.

Город Нижний Новгород является крупным городом в Приволжском регионе.

Он расположен у слияния великих рек, что сыграло важную роль в развитии.

Город славится богатой историей.

Архитектура города сочетает старинные постройки и новые районы.

Нижний Новгород новости в телеграмм каждый день

Здесь активно развивается деловая среда.

Повседневная жизнь города отличается насыщенностью и множеством событий.

Он является крупным логистическим центром.

Таким образом, Нижний Новгород остаётся привлекательным городом для людей разных интересов.

Умение стильно одеваться играет ключевую роль в самовыражении.

Она помогает передать настроение и выглядеть гармонично.

Грамотно подобранный образ влияет на то, как человека оценивают другие люди.

В повседневной жизни одежда может повышать самооценку.

https://forums.maxperformanceinc.com/forums/member.php?u=202766

Стильный образ облегчает социальные контакты.

При этом важно учитывать индивидуальные особенности и уместность ситуации.

Мода дают возможность находить новые решения.

В итоге, умение стильно одеваться становится полезным навыком.

Стильная одежда играет значимую роль в создании первого впечатления.

Она помогает подчеркнуть индивидуальность и почувствовать уверенность.

Грамотно подобранный образ влияет на то, как человека воспринимают окружающие.

В повседневной жизни одежда может добавлять уверенности.

https://bryggeriklubben.se/wiki/index.php?title=%D0%9B%D0%B5%D0%BE%D0%BF%D0%B0%D1%80%D0%B4%D0%BE%D0%B2%D1%8B%D0%B9_%D0%BF%D1%80%D0%B8%D0%BD%D1%82

Стильный образ облегчает деловые встречи.

При этом важно учитывать личные предпочтения и уместность ситуации.

Современные тенденции дают возможность экспериментировать.

В целом, умение стильно одеваться влияет на общее восприятие личности.

Premium watches continue to attract attention despite the rise of modern gadgets.

They are often seen as a sign of prestige and refined taste.

Skilled engineering plays a major role in their lasting value.

Many luxury watches are produced using premium components.

https://members.mcafeeinstitute.com/read-blog/2257

They also represent a rich heritage passed down through generations.

For collectors, these watches can serve as both practical items and collectible pieces.

Elegant styling allows them to stay relevant across changing fashion trends.

Ultimately, luxury watches continue to interest buyers around the world.

Стильная одежда играет важную роль в самовыражении.

Она помогает подчеркнуть индивидуальность и чувствовать себя увереннее.

Современный стиль влияет на восприятие окружающих.

В повседневной жизни одежда может помогать собранности.

https://telegra.ph/Moncler-12-25

Продуманный гардероб облегчает социальные контакты.

При выборе одежды важно учитывать индивидуальные особенности и контекст.

Актуальные стили дают возможность обновлять образ.

Таким образом, умение стильно одеваться помогает чувствовать себя увереннее.

Having a stylish appearance is important for making a good impression.

It helps highlight individuality and boost self-esteem.

A coordinated look affects social perception.

In daily life, clothing can increase self-assurance.

https://telegra.ph/Salvatore-Ferragamo-12-25

Thoughtful clothing choices support professional encounters.

It is important to consider personal preferences and the context of the event.

Modern styles allow people to experiment with looks.

In conclusion, dressing stylishly helps feel confident.

Недропользование — это совокупность процессов, связанный с изучением и использованием недр.

Оно включает разведку полезных ископаемых и их рациональное использование.

Данная сфера регулируется законодательством, направленными на безопасность работ.

Грамотный подход в недропользовании обеспечивает устойчивое развитие.

Health follows us through every decision, every emotion, every routine.

Even with so many rules and systems, we often feel more confused than informed.

And the more we follow, the further we drift from our own balance.

Real health begins the moment we stop forcing and start listening.

Every body has its own rhythm.

Patience turns into clarity.

Everyday actions—walking, breathing, eating—become moments of connection.

When we stop chasing perfection, clarity arrives naturally.

When the idea of gentle awareness feels more natural than pressure.

To rediscover the quiet patterns that shape your well-being.

Patience over perfection.

Every insight brings us closer to understanding what health really means.

What feels like intuition is often grounded in clear biological patterns.

Have you ever thought about how this relates to tadacip vs cialis.

Whether we pay attention or not, health lives at the core of how we exist.